A history lesson on the success of Keymer Tiles

Many generations worked in the ‘brickyard’ over the decades that it was open before its closure in 2013. It was renowned for being the largest employer in town.

In some families generations worked there, helping excavate clay and make bricks and tiles that have gone into building thousands of homes, offices, and factories.

Advertisement

Hide AdAdvertisement

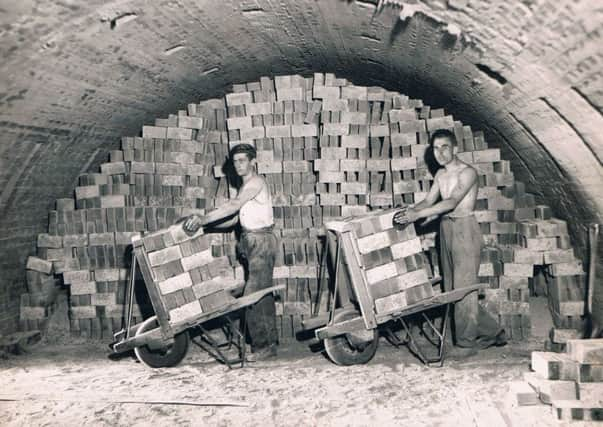

Hide AdMany men worked on the site, including the men that are pictured.

Jim Heath, worked at the Nye Road site from 1936 and 1977. Due to the routinely tough work that these men were subdued to Jim had to retire at the age of 63, under medical reasons.

Working along side Jim, there was: George Rich, Jack Stelle, Tom Walden, Tom Burd, Ron, Heaseman, Jim Hunt, Jim Dennat, Harold Harris, Arthur Smith and Fred Urry - who are pictured bottom left.

Jim Heath, grandson Adrian, told the Middy his memories of visiting his grandad at the yard: “Occasionally at weekends he would take me around the site to show me where and how the bricks and tiles were moulded and then fired in the kilns.

Advertisement

Hide AdAdvertisement

Hide Ad“This place to me was both magical and alien at the same time. The sheds had a very distinctive smell about them that I have not encountered since.”

He then continued to say: “Visit any industrial facility in 2018 and you will be bombarded by notices reminding employees that use of personal protective equipment (PPE) is mandatory and failure to comply in its use will result in removal from site.

“PPE? There was none of that nonsense in his day. The only PPE I recall was shall pieces of rubber cut at home from old tyres (as seen on my Grandfather’s left hand that as he unloads the kiln). These were to provide the hands some protection from the abrasiveness of the bricks.”

The yard evolved from the former Ditchling Potteries, a collection of various works including Dunstalls Farm owned by John Billinghurst, John Palmer and John Pomfrey.

Advertisement

Hide AdAdvertisement

Hide AdThe Ditchling Common site exhausted its supply of clay and production moved to Nye Road between 1860 and 1940.

The works were once reputed to be the largest in the South and employed more than 300 people.

Its red terracotta ware won awards in London in 1862 and Philadelphia in 1876 and was used throughout the British Isles and, largely due to its early success, was re-introduced by the modern-day Keymer in the early 1990’s.

In early days the tall brick chimneys belching smoke were a familiar sight, long since demolished to meet clean air laws.

The site kilns went cold years ago now and the clay pits are currently being redeveloped with a large housing estate being erected. So ended an industry that had thrived for 500 years.